HACCP Certification Training Info

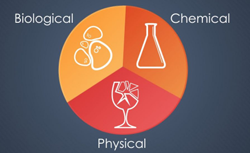

Hazard Analysis and Critical Control Points (HACCP) is a type of preventive food safety system that involves identifying physical, biological and chemical hazards right during food handling and preparation stage. Learn more about HACCP with the following:

- HACCP Intro

- 7 Principles

- Food Hazards

- HACCP Glossary

HACCP Introduction

.jpg) HACCP (Hazard Analysis Critical Control Point) is the internationally recognized risk-based system for managing food safety and involves identifying physical, biological and chemical hazards during food handling and preparation stage.

HACCP (Hazard Analysis Critical Control Point) is the internationally recognized risk-based system for managing food safety and involves identifying physical, biological and chemical hazards during food handling and preparation stage.

The HACCP system has two major components.The "HA" of HACCP represents the logic in the hazard analysis which identifies the where and how of hazards. The "CCP" of HACCP represents the critical control points that provide the control of the process and the proof of the control.

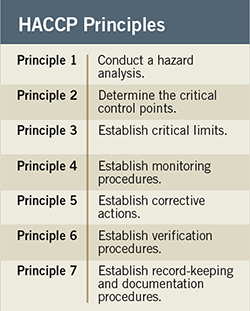

HACCP is comprised of 7 principles that are the core of the application process of HACCP to a food safety program.

Developing a HACCP Plan

To start a HACCP system, a company must first write a HACCP plan. Companies may use generic models as resources for developing a plant specific plan, however, the most useful and successful HACCP plans need to be developed from the very beginning from the plant that will use and implement the plan.

To develop a HACCP plan, a team of individuals from within the company, with some assistance from outside experts, conducts five preliminary steps and applies the seven HACCP principles.

The five preliminary steps are:

- Bring together the HACCP resources/assemble the HACCP team.

- Describe the product and its method of distribution.

- Develop a complete list of ingredients and raw materials used in the product.

- Develop a process flow diagram.

- Meet the regulatory requirements for Sanitation Standard Operating Procedures (SOP's).

The seven HACCP principles are the most important steps in writing a HACCP plan. The first two steps provide the foundation for the HACCP plan. These two steps are essential since application of the other HACCP principles depend on the results of the hazard analysis. The remaining five steps are the application steps of the HACCP plan and provide the structure for conducting the workings of the HACCP plan int he processing plant.

Seven Principles of HACCP

HACCP is based on seven principles:

HACCP is based on seven principles:

- Principle 1 - Conduct a Hazard Analysis

- Principle 2 - Determine Critical Control Points (CCPs)

- Principle 3 - Establish Critical Limits

- Principle 4 - Establish Monitoring Procedures

- Principle 5 - Establish Corrective Actions

- Principle 6 - Establish Verification Procedures

- Principle 7 - Establish Record Keeping and Documentation Procedures

Principle 1: Hazard Analysis. This involves deconstructing the production process and identifying the physical, chemical and biological hazards present in each process. Control measures have to be planned during this stage.

Principle 2: Critical Control Points. Critical control points are the phases of the production process where you apply control measures that will contain and eliminate existing risks and make food safe for consumption.

Principle 3: Critical Limits. The critical limit is the safety limit to which the hazard can be safely controlled. It essentially draws the line between safe and unsafe food handling and storage.

Principle 4: Monitoring Procedures. The US Food Safety Inspection Service enforces the inclusion of monitoring activities in a business’s HACCP plan. Monitoring activities should be established to make sure that hazards are controlled at each CCP.

Principle 5: Corrective Actions. These are procedures that are conducted as a means of correcting deviations from the set critical limits at each CCP. These procedures intend to ensure that the food poses no harm to consumers because of the deviation.

Principle 6: Verification. Verification procedures review the effectiveness of the HACCP system in controlling hazards. These activities include but are not limited to quality checks, food samplings and microbial testing.

Principle 7: Record Keeping. Documents provide proof that the HACCP system is working effectively. It includes anything from changes in the HACCP plan implementation, monitoring and verification activities, critical control points and limits set by the business, to invoices and receipts.

Food Hazards

HACCP focuses on three types of hazards: biological hazards, chemical hazards, and physical hazards.

HACCP focuses on three types of hazards: biological hazards, chemical hazards, and physical hazards.

Biological Hazards

Biological hazards occur when hazardous or pathogenic organisms are introduced to food and thus pose a food safety concern to consumers. Biological hazards include bacteria, viruses and parasites of public health significance.

Biological hazards can be introduced to food from the environment (e.g. soil bacteria, agricultural run-off) or from inadequate sanitation practices and cross contamination during transportation, handling, processing, and storage (e.g., poor food hygiene practices). The type and magnitude of microbial growth is determined in part by the nature of the food, package conditions and storage environment.

Bacteria that are the most prevalent in the United States include E. coli 0157:H7, Listeria monocytogenes, Salmonella, Staphylococus auerus, and Campylobacter.

Chemical Hazards

Chemical hazards occur when chemicals are present in foods at levels that can be hazardous to humans. Contamination may occur through various pathways:

- The environment (air, soil, water),

- Intentional use of chemicals, such as pesticides and veterinary drugs,

- Manufacturing processes,

- Addition of food additives.

In the food industry, there are various types of chemical hazards, some notable ones include:

- Mycotoxins

- Natural Toxins

- Marine Toxins

- Environmental Contaminants

- Food Additives

- Processing-induced chemicals

- Pesticides/Agricultural Products and

- Veterinary Drug Residues

Physical Hazards

Physical hazards covers all materials (excluding bacteria and their by-products (toxins), viruses and parasites) which may be found in a food that are foreign to that particular food. These materials are usually non-toxic but are associated with unsanitary conditions of production, processing, handling, storage and distribution of food. Some examples of extraneous materials that may be found in food are insects, hair, metal fragments, pieces of plastic, wood chips and glass.

Allergenic Hazards

Food allergies also represent a hazard to some people. A food allergy is an abnormal response to a food triggered by your body's immune system. Symptoms of an allergic reaction can range in severity from a skin rash or slight itching of the mouth, to migraine headaches, to anaphylactic shock and death.

The foods that most often trigger allergic reactions are:

- Peanuts

- Tree nuts (almonds, Brazil nuts, cashews, hazelnuts, macadamia nuts, pecans, pine nuts, pistachio nuts, and walnuts)

- Sesame seeds

- Milk

- Eggs

- Seafood (fish, crustaceans, and shellfish)

- Soy

- Wheat

- Sulphites

- Mustard

HACCP Glossary

- Acid Food – A food that has a natural pH of 4.6 or below.

- Bacteria – Bacteria are found in all foods. Most are killed by high temperatures, but some form toxins which may or may not be killed by heat.

- Calibration – the process of standardizing a temperature monitoring instrument to ensure that it will measure within a specific temperature range in which the instrument is designed to operate.

- CCP Decision Tree: A sequence of questions to assist in determining whether a control point is a CCP.

- Chemicals – Chemical food born illnesses are among the most deadly. Chemicals and other “natural” toxins formed in food include agents such as scombrotoxin and ciguatoxin. Store cleaning supplies in a different area away from stored food.

- Control (verb) – To take all necessary actions to ensure and maintain compliance with criteria established in the HACCP Plan.

- Control Point: Any step at which biological, chemical, or physical factors can be controlled.

- Corrective Action: Procedures followed when a deviation occurs.

- Criterion: A requirement on which a judgment or decision can be based.

- Critical Control Point: A step at which control can be applied and is essential to prevent or eliminate a food safety hazard or to reduce it to an acceptable level.

- Critical Limit: A maximum and/or minimum value to which a biological, chemical, or physical parameter must be controlled at a CCP to prevent, eliminate, or reduce to an acceptable level the occurrence of a food safety hazard.

- Deviation: Failure to meet a critical limit.

- HACCP: A systematic approach to the identification, evaluation, and control of a food safety hazard.

- HACCP Plan: The written document that is based on the principles that is based on the principles of HACCP and that delineates the procedures to be followed.

- HACCP System: The result of the implementation of the HACCP plan.

- HACCP Team:The group of people who are responsible for developing, implementing, and maintaining the HACCP system.

- Hazard:A biological, chemical, or physical agent that is reasonably likely to cause illness or injury in the absence of its control.

- Hazard Analysis: The process of collecting and evaluating information on hazards associated with the food under consideration to decide which are significant and must be addressed in the HACCP plan.

- Monitor: To conduct a planned sequence of observations or measurements to assess whether a CCP is under control and to produce an accurate record for future use in verification.

- Oxidation-reduction (redox) potential: Reactions involving electron transfers; the reductant donates electrons to an oxidant.

- Pathogen: A disease causing organism.

- Parts per million (ppm): The number of parts of a substance in 1,000,000,000 parts of another substance. (1 ppm = 1 inch in 16 miles)

- pH: pH is the measure of the hydrogen ion activity of a solution and is defined as the negative logarithm of the hydrogen ion concentration.

- Prerequisite Programs: Procedures, including Good Manufacturing Practices that address operational conditions providing the foundation for the HACCP system.

- Severity: The seriousness of the effect(s) of a hazard.

- Spore: A differentiated, specialized form that can be used for dissemination, for survival of adverse conditions because of its heat and desiccation resistance, and/or for reproduction. Spores are usually unicellular and may develop into vegetative organisms or gametes. They may be produced asexually or sexually and are of many types.

- Step: A point, procedure, operation, or stage in the food system from primary production to final consumption.

- Toxin: A microbial product or component that can injure anther cell or organism at low concentrations. Often the term refers to a poisonous protein, but toxins may be lipid or other substances.

- Validation: That element of verification focused on collecting and evaluating scientific and technical information to determine whether the HACCP plan, when properly implemented, will effectively control the hazards.

- Verification: Those activities, other than monitoring, that determine the validity of the HACCP plan and that the system is operating according to the plan.

- Water Activity (aw): A quantitative measure of water availability in the habitat; the water activity of a solution is one-hundredth its relative humidity.